EPS (expanded polystyrene) and STYROFOAM™ Brand Foam can both be used for carving or sculpting. Each has their own unique properties that may be advantageous for a particular project. STYROFOAM™ Brand Foam is available in sheets ranging from ¾” thick to 4” thick in widths up to 48” and lengths of 96”. Because of the manufacturing process used to produce the extruded polystyrene panels, the surfaces of the panels are smooth and have a “skin” on each of the large surfaces. Some artists that use CNC routers prefer the STYROFOAM™ Brand Foam for creating signs or large letters because of the smooth finish. Letters can be easily cut out with a router and the surface can either be painted or coated with a variety of special purpose products. One of the disadvantages of the STYROFOAM™ Brand Foam is that it is not available in block form for larger products.

EPS or expanded polystyrene is the white rigid foam commonly, but mistakenly, called STYROFOAM™. EPS is manufactured by first puffing tiny beads then molding those puffed beads into very large blocks. The block size varies from factory to factory but they typically range between 30” x 48” x 192” all the way up to 50” x 70” x 290”. These large blocks are then cut into slabs or shapes or smaller blocks depending upon the requirements of the project. EPS is also available in a variety of densities from just under 1 lb per cubic foot to 3 lbs per cubic foot. Denser material is also available for special applications.

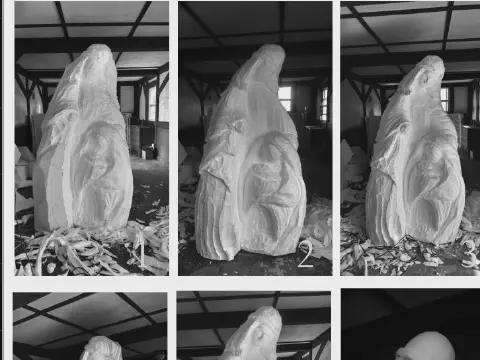

EPS is the preferred sculpting medium by a lot of artists because it is lightweight and easy to move abound. A block 3’ x 4’ x 8’ of .9 lb density EPS weighs less than 87 lbs. It is best carved with a hot knife or hotwire bow cutter but can also be carved with a serrated knife, chain saw, hand saw and even an electric carving knife. The finished product can then be coated with a variety of coatings manufactured specifically for EPS. Available coatings can create finishes that are very smooth to very course depending upon needs of the sculptor.