Using EPS forms in bridge construction is a popular way to achieve accurate concrete pours, whatever the bridge size. At Universal Foam Products, we can advise you on using form liners in all areas of bridge building.

In Monticello, Indiana, the U.S. 24 Bridge, also known as the Washington State Bridge and built more than 70 years ago, was to be replaced by a new bridge just north of the original. The new bridge, as with its predecessor, had to span the Tippecanoe River based on four piers of varying heights across the water.

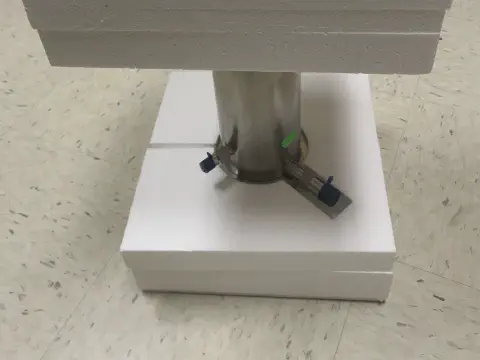

The bridge construction team wanted to use EPS (expanded polystyrene foam) as form liners to guide the concrete for each of the piers to be constructed. The piers varied in height from 29’ to 43’ so this was a significant build. After discussion with the Universal Foam Products teams they used the .9 lb density EPS for the form liners. This lighter weight choice of EPS foam could be used as the concrete was to be poured in short lifts.

The scale and height of the piers can be seen in the construction photos on our Projects Gallery. EPS forms are cut to match the bridge’s architectural specifications on our CNC equipment and shipped directly to site. And as with using EPS blocks and shapes in any construction environment, they are very easy to move about on site – far less need for heavy lifting equipment.

Once the new bridge was finished, the previous bridge was taken down and removed. Since the opening of the new bridge, there have been proposals to rename it to honor the service of a local serviceman, missing in action.

For all advice on bridge construction with EPS forms, call our team now at 410-498-0000.