Polystyrene beads are often mistakenly referred to as STYROFOAM™ beads. The puffing of EPS resin, creating the puffed polystyrene beads is the first step in producing EPS (expanded polystyrene) blocks. Puffed polystyrene beads are used for several different applications besides the manufacture of EPS blocks. Two of the most common are the production of bean bag chairs and the production of lightweight concrete.

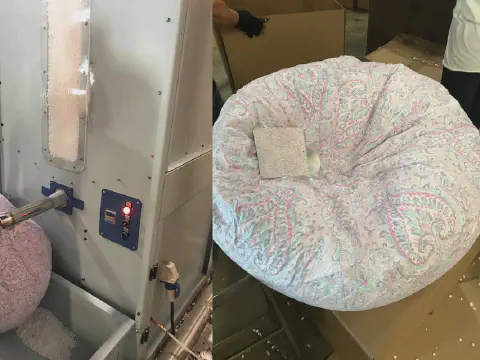

To create the puffed beads the EPS resin is puffed by applying steam to the resin in an enclosed chamber. The Pentane gas in each bead expands from the heat causing the beads to grow by 30 to 35 times their original size. When they are fully puffed the beads are primarily made up of air. The puffed beads are then transferred to a drying chamber where they are subjected to dry air and from there into large poly bags for shipping. For very large applications the puffed beads can be blown directly into a 53’ trailer. Most people are familiar with bean bag chairs. They were very popular in the 60’s and in recent years have seen a resurgence in popularity during the past couple of years. When the puffed beads arrive at the chair manufacturer they are blown into the shell using special equipment and the shell is sealed.

The puffed EPS beads are economical filler with unique properties that could not be obtained using any other material. In construction, the most common use of polystyrene beads is in the production of lightweight concrete. Standard concrete weighs 150 lbs per cubic foot. Puffed polystyrene beads weigh just under 1 lb per cubic foot. There are applications when the strength of concrete is needed but the weight of the concrete is a problem. One solution is to mix puffed polystyrene beads into the concrete mix. As the puffed beads displace the other components of the concrete mix the material becomes lighter. The more beads are added, the less strength the concrete has also, so the final portions are governed by the application of the concrete.

Another application in construction for polystyrene beads is retrofit insulation of un-insulated exterior walls. In this application, the puffed beads are poured into the wall cavity between the studs by drilling a hole in the top of the wall. If the puffed beads fill the cavity the space can obtain R-values close to that of fiberglass insulation. The problem with this method is the installation. Polystyrene beads are full of static electricity and they stick to everything. It is impossible to determine if the space has been filled or if there are large pockets of air remaining. This method of insulation can also be very messy for the same reasons.