Many major construction projects need lightweight earthwork void fill. Selecting void fill that can also reduce loading on floors, foundations and parking decks means taking a look at EPS 60 psi foam – one of the higher psi ratings available from Universal Foam Products. In Arlington, Virginia an incredible 65,000 cubic feet of 60 psi EPS foam was supplied for both its compressive strength and ease of use onsite.

The ReNew Arlington Project in Arlington, Virginia is an ongoing redevelopment to boost commercial corridors in Arlington. Construction work in and around Jacksonville University includes the improvement of roads, landscaping and sidewalks. Our client was involved in the construction of an underground parking garage in this development and needed to reduce the loading on top of it. As can be seen from the construction in progress, a significant amount of lightweight void fill was required, but only at the right compressive strength specification.

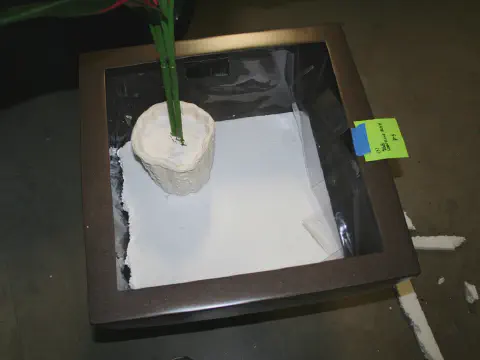

The engineer selected 60 psi EPS (expanded polystyrene) foam for this load-bearing application. This foam weighs in at 3 lbs per cubic foot with the strength required but still light enough to handle on site with minimal equipment. The blocks supplied were 48” x 96” and in various thicknesses. For the onsite cutting required, two Geofoam Hotwire Kits were also supplied – one of the most versatile and popular cutting tool used onsite. Once shaped, the EPS blocks can be set into place by hand in many areas where loose void fill materials wouldn’t be suitable.

All these factors mean reduced projects costs as well as the project achieving its load-bearing specifications. For more specialist advice on specifying EPS foam with high compressive strength, call our engineering teams at Universal Foam Products on 410-498-0000