Rising summer temperatures means pool construction deadlines need to be hit before the summer. Or pools are being filled to make way for other leisure or hospitality areas. How does using EPS Geofoam reduce time and effort on site – particularly in dealing with swimming pool contracts?

EPS blocks for new pools – quick to move and install

EPS foam blocks and billets can be used throughout the construction of the swimming pool. For regular shaped pools, blocks of EPS geofoam are laid quickly to form the floor and walls. They are easy to move about a busy site where maybe other construction areas of a hotel may be in progress. For pools with vertical contours, seats, slopes and steps, EPS foam can be easily shaped also.

On a rooftop pool, EPS blocks are sometimes the only viable option that doesn’t add weight issues to a build in a restrictive area.

EPS Blocks for pool infill – easy to cut and shape on site

For pool infill projects they give the same advantages, lightweight to handle and get to site and then a strong but lightweight fill for a pool wherever it is located.

Infill pool success in just two days

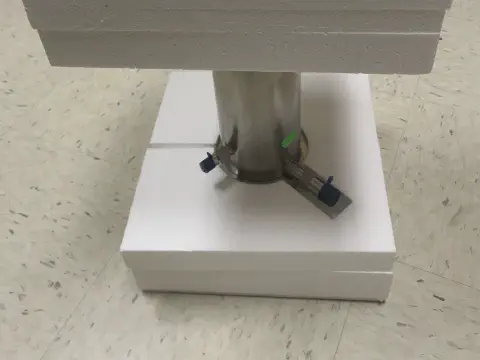

In a second successful project for a swimming pool infill in Maui, the contractor bought 36 blocks or billets of EPS15 Geofoam – at 36” x 48” x 96”. To make the regular accurate cuts needed, he also purchased the Geofoam Hotwire Kit from Universal Foam Products. All cutting was done on site with our team providing much welcomed advice on cutting technique – a great customer service bonus. Infilling pools with EPS blocks means good prices for the material itself PLUS minimal time on site. The Maui pool project was completed in 5 days with just two people working with the blocks.

To see more examples of how EPS foam from Universal Foam Products has shaped pools throughout the country, take a look below!