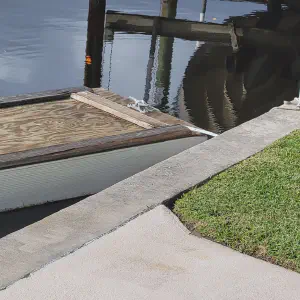

Every year the American Society of Civil Engineers sponsors a worldwide competition between engineering schools to build and race a concrete canoe. Because we ship EPS from locations throughout the United States, Universal Foam Products has been providing EPS blocks and finished forms for construction of the canoes to colleges around the country. Some schools purchase blocks of EPS and do their own shaping, while others purchase the blocks already finished in the shape of the interior of the canoe. These photos show pieces of the process from block to finished canoe form.

First the basic shape is cut using a CNC hotwire cutter. Next those rough-cut pieces are taken to a milling machine where a 5-axis router cuts the final shape. The finished pieces are then glued together to create the inside negative form of the canoe.

Let Universal Foam Products quote the blocks for you to cut or the finished forms for your entry in the ASCE concrete canoe competition.